Breakage modelling of clay cylinders along the feed process to a kiln

Project Description

IMERYS Technology Center (IMERYS), world leader in mineral specialties for industry, called upon ITASCA France (ITASCA) to monitor and understand the mechanical evolution of cylindrical clay blocks along the feed process of their rotary kilns. The material passes from the dryer to the kiln inlet, via several conveyor belts, a bucket conveyor, successive chutes, flow pipes and a storage silo.

On-site observations show a homogeneous block size, corresponding to the optimum performance of the end-product manufacturing process at the dryer outlet, but a particularly wide size distribution, from powder to initial dimensions, when they enter the kiln. Knowing that the quality of the production depends on the size distribution of the injected material, it is necessary to control this parameter.

The aim of this project is to understand the origin of the evolution of block size, by analyzing the various transition zones that can cause high mechanical stresses, and then to optimize the process, by limiting block breakage and abrasion.

ITASCA's Role

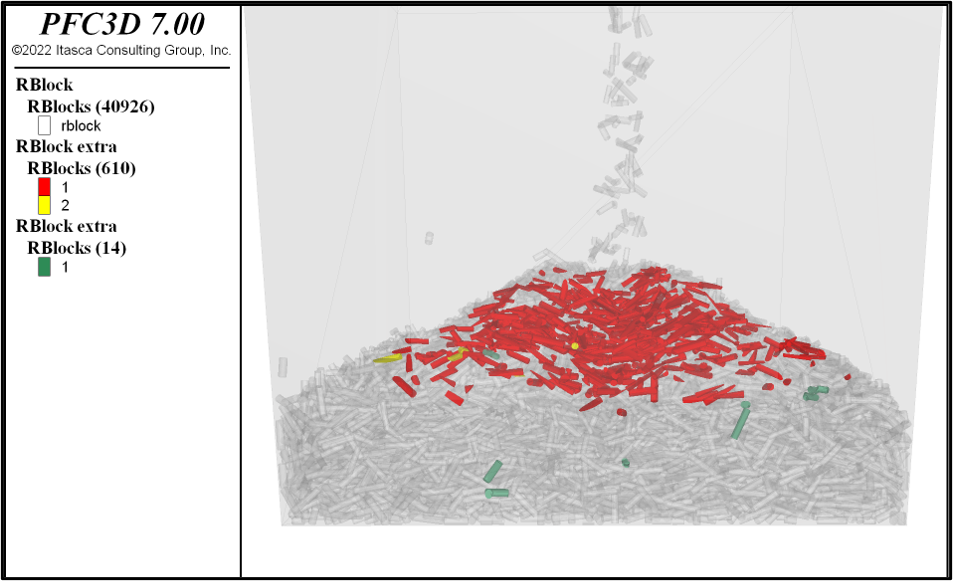

ITASCA carried out discrete numerical simulations of the most critical zone: on-site observations highlighted that the zone concerned was the discharge zone in the storage silo, as the blocks were subjected to a fall of several meters.

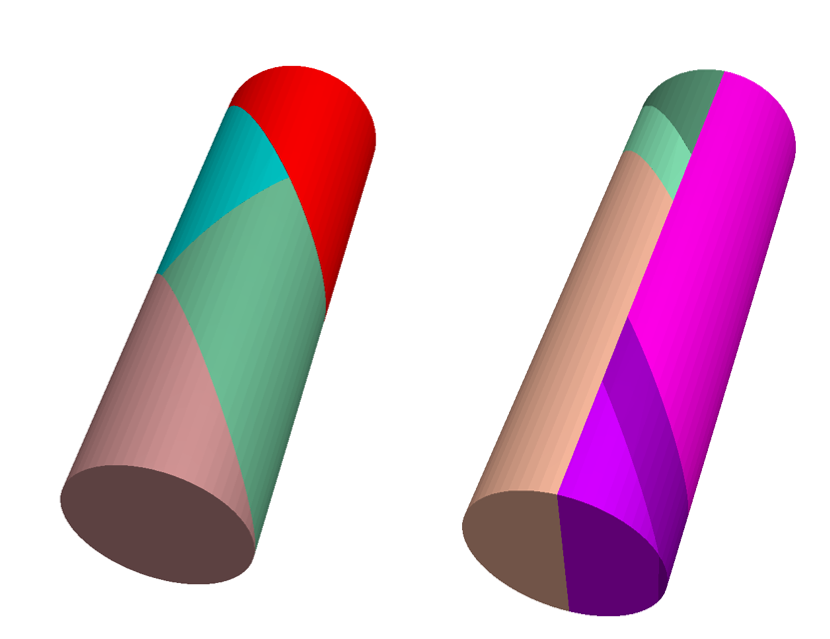

A long calibration phase was carried out to calibrate the mechanical properties of the individual cylinders (each block being breakable into several sub-blocks): elastic properties, block strength and friction coefficients were calibrated on simple compression tests and angle-of-slope tests, then validated on a Casagrande shear box test. Damping properties were then set by reproducing cylinder rebound tests (compared with laboratory tests using a high-speed camera).

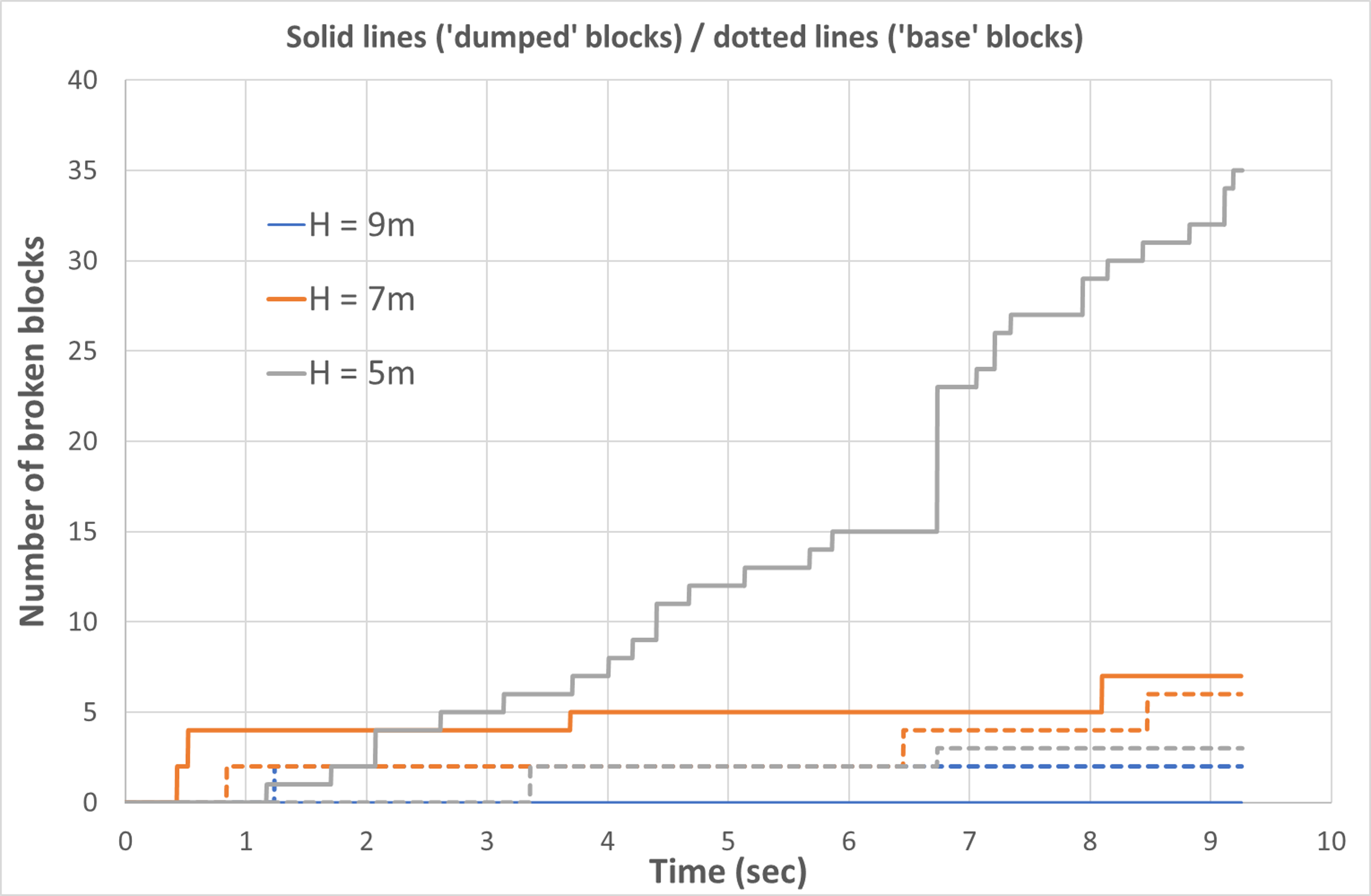

Finally, the filling phase of the silo was modeled and the influence of the drop height and length of the poured blocks, on the block breakage rate, was studied.

Project Results

- Experimental results well numerically simulated and calibrated.

- Complex numerical parameter settings: need for more precise and systematic laboratory characterization to improve the model.

- Numerical models show that blocks do not break as they fall, but when they hit the surface of the bank.

- Influence of the drop height: the higher the drop height, the greater the number of broken blocks.

- Influence of cylinder length: the longer, the more breakable.