Electrical resistivity and air permeability of a model baked anode material

Project Description

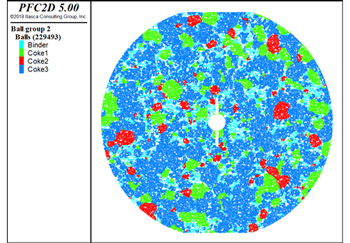

A baked anode is a complex material, that results from the mixing and baking of different petrol coke grains, with different size distributions, with a pitch binder. A PFC2D model accounting for the microstructure of a baked anode, using the Bonded Particle Model (BPM) has been developed in previous studies (ICSAS16-CST-MFG- 35143-01 and ICSAS17-CST-MFG-35187-01).

The new goals are to: 1) calculate electrical resistivity, and 2) calculate permeability in the modelled material then calibrate micro-properties and study how it is affected by bonded contact, fractions and pores for these two properties.

Itasca's Role

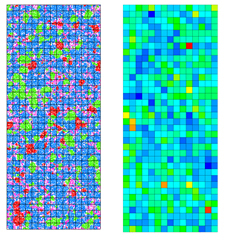

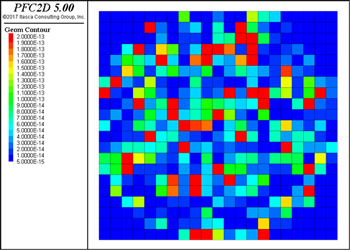

Develop a numerical method to measure electrical resistivity based on the existing contact network in the discrete sample. The relation takes into a account the porosity of the sample (or Representative Elementary Volume) and its volume as well as contact properties such as the thermal resistance of pipes (to be calibrated), their length and their orientation.

Build a numerical method to calculate the permeability of the assembly based on the Kozeny Carman theory.

Both approaches allow local measurements to be made and provide the ability to analyze the evolution of these properties during the simulation.

Project Results

Modifying the volume fraction of material (in the range value tested) only slightly modifies the electrical resistance of the sample (+ or - 2%). The contact network is more or less the same in all samples tested which explains these small differences.

Modifying the volume fraction of material and/or the pores/voids ratio does not change the permeability, since the grain distributions for all material are equal and porosity is randomly distributed in materials. The permeability of the medium will be influenced mainly by a difference in granulometry and porosities from one material to another.