Generic Adhesive Contact Model

The Adhesive Rolling Resistance Linear Model is a new contact model now available in PFC 6 to represent a simple cohesive granular material. It is based on the two-dimensional model of Gilabert et al. (2007). The cohesion arises from a short-range attraction, which is a linear approximation of the van der Waals force law. The short-range attraction differs from the PFC bonded materials in that there is no concept of breakage (i.e., the attraction is always present whenever the interacting surfaces come within a specified attraction range). Gilabert et al. (2007) state that assemblies of cohesive grains exhibit much larger variations in their equilibrium densities than do corresponding assemblies of non-cohesive grains, because the cohesive grains may form loose, solid-like cohesive granulates. Such granular systems can stay in mechanical equilibrium at lower solid fractions (down to 25-30%) than cohesionless granular systems (with typical solid fractions of 58-64%). Cohesive granular materials have much less frequently been investigated by numerical simulation than cohesionless ones. The new contact model in PFC encompasses both types of materials and could be used to study macroscopic behavior of a variety of cohesive granular materials including cohesive powders such as xerographic toners (in which cohesion stems from van der Waals interaction) and wet bead packs (in which cohesion stems from liquid bridges joining neighboring particles).

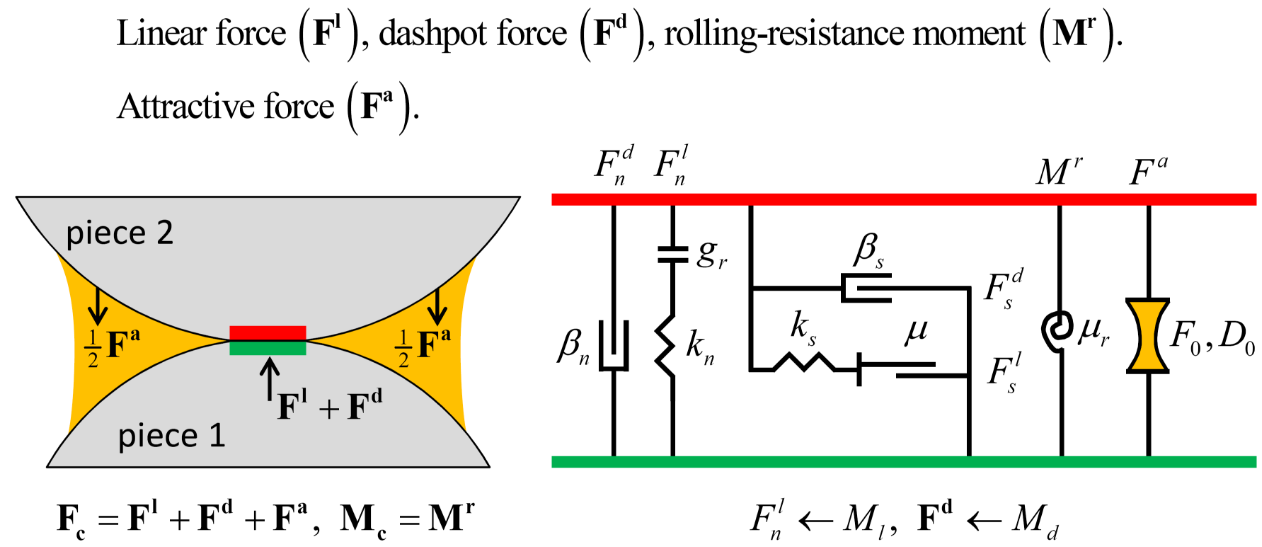

This contact model provides the behavior of a cohesive granular material via a short-range attraction as a linear approximation of the van der Waals force by adding a cohesive component to the rolling resistance linear model. It is a linear-based model that can be installed at both ball-ball and ball-facet contacts. The cohesive component is characterized by two parameters: the maximum attractive force (F0), and the attraction range (D0), as in the following figure.

A contact with the adhesive rolling resistance linear model is active if and only if the surface gap is less than the attraction range, then the force-displacement law is skipped for inactive contacts. In addition to the energy partitions of the rolling resistance linear model, the adhesive rolling resistance linear model also partitions adhesive energy (i.e., work done by the attractive force on the contacting pieces). Refer to Gilabert et al. (2007) and Gilabert et al. (2008) for additional information about the structure and mechanical properties of cohesive granular materials as well as additional examples of cohesive packings studied in the laboratory.

Soft-Bond Contact Model

The soft-bond model can be used to simulate both unbonded and bonded systems.

In an unbonded state, it behaves essentially similar to the contact model proposed by Jiang (2015), providing the ability to transmit both a force and a moment at the contact point, with frictional strength parameters limiting the shear force, bending moment, and twisting moment.

In its bonded formulation, the behavior is similar to that of a linear parallel bond model, with a frictional strength parameter limiting the shear force, and the possibility for the bond to fail if the bond

strength is exceeded either in shear or in tension. However, contrary

to the linear parallel bond model, the bond is not removed upon failure.

Instead, it may enter into a softening

regime until the bond stress reaches a threshold value at which the

bond is removed and considered broken. The slope and tensile breakage

strength during softening can be

specified by the user (via the softening factor and the softening

tensile strength factor, respectively). Another difference with the

linear parallel bond model is that only one set of stiffnesses is used

for both the unbonded and bonded formulations. This behavior is

essentially similar to that proposed by Ma (2018),

with the difference that the bond elongation used to update the normal

stress in the softening regime accounts for both the normal displacement

and bending increments.

Behavior Summary

A soft bond can be envisioned as a set of elastic springs with

constant normal and shear stiffnesses, uniformly distributed over a

{rectangular in 2D; circular in 3D} cross-section lying on the contact

plane and centered at the contact point. Relative motion at the contact

causes a linear force and moment to develop, that act on the two

contacting pieces. If the bond is inactive, frictional strength

parameters cap the shear force, bending and twisting moments. If the

bond is active, the force and moment can be related to maximum normal

and shear stresses acting within the bond material at the bond

periphery. If either of these maximum stresses exceeds its corresponding

bond strength, the bond may enter a softening regime to a specified

failure criteria. After failure, the behavior reverts to the unbonded

formulation.